Reconditioning programs

Extend your machine’s lifetime

and boost your Return

On Investment thanks to our reconditioning programs

Extend your machine’s lifetime

and boost your Return

On Investment thanks to our reconditioning programs

can be maintained

over time with regular tools reconditioning

is maximized through the reconditioning

of machines

and their resulting lifetime extension

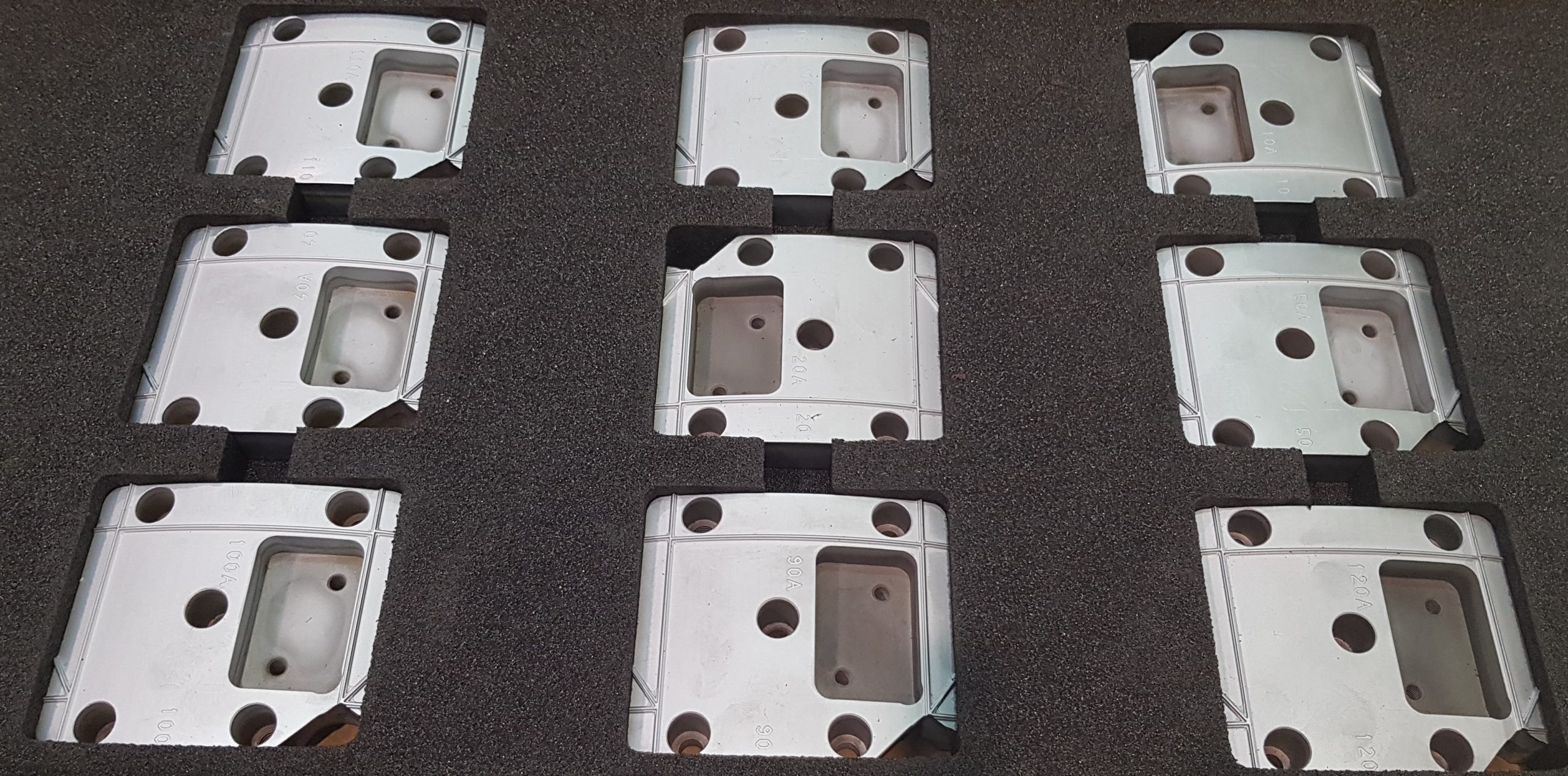

The quality of the Komori-Chambon cutting tools allows up to 3 resharpening operations. This can be done on-site or in our plant. Resharpened tools guarantee fast and high precision converting jobs.

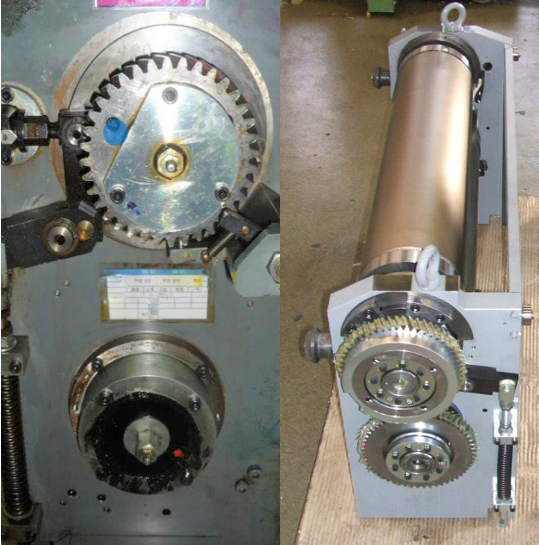

Complete cassette reconditioning can be proceeded for extra years of serenety and productivity.

The printing cassettes can be reworked individually or as part of a reconditioning program

which aims at decreasing the unit prices.

The program also enables a reduction of the leadtime. Komori-Chambon provides

a shuttle crate for the shipment of the first cassette.

The following cassettes can be shipped gradually, along 18 months.

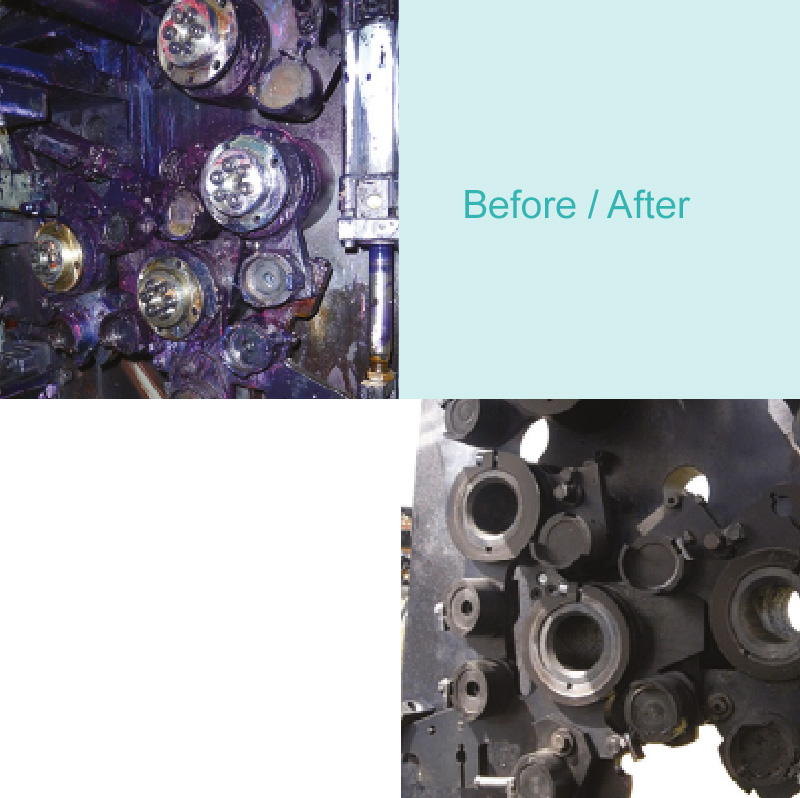

If your machine is still in line with your production targets but needs to be refurbished, get it reconditioned in our plant. We handle the process from A to Z: from transport to final re-installation at your facility.