Support functions

Each project mobilizes teams supporting our customers, from the identification of needs down to the daily business follow-up.

The involvement of all members of Komori-Chambon is the key to our relationship quality over time.

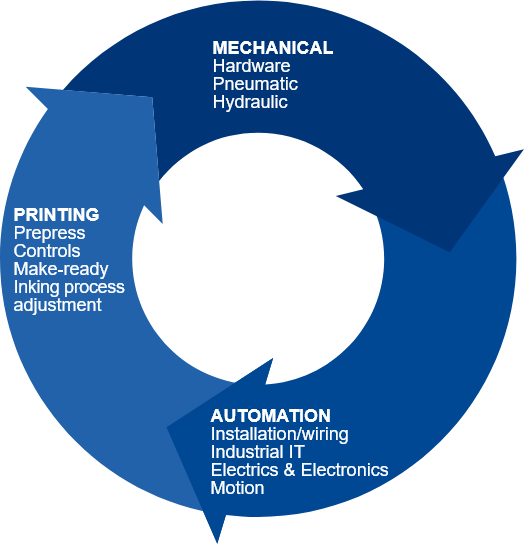

The Komori-Chambon design office gathers all skills required to build and run a full production line.

This comprehensive knowledge is necessary for:

Komori-Chambon ensures the control of carton board all along the production line, including OEM elements, for the best printing, converting and delivery quality level.

The development of our machines and tools include Industry 4.0 specificities :

Each project mobilizes teams supporting our customers, from the identification of needs down to the daily business follow-up.

The involvement of all members of Komori-Chambon is the key to our relationship quality over time.

Our area sales managers initiate the relationship and follow-up the activity.

Once the project is finalized and the machine ready to ship, they are backed up by the service team for the installation, commissioning and start-up. These technicians also ensure the after-sales service and training.

The spare parts team is there to ensure a smooth maintenance management.

The logistics department is highly experienced and able to arrange deliveries on all continents in the safest conditions and shortest lead-times. 99% of our turnover are realized as export sales, 2/3 outside Europe.

Other departments contribute to a smooth partnership, including purchasing, IT, accounting. Komori-Chambon is fully focused on the quality of our relationship.