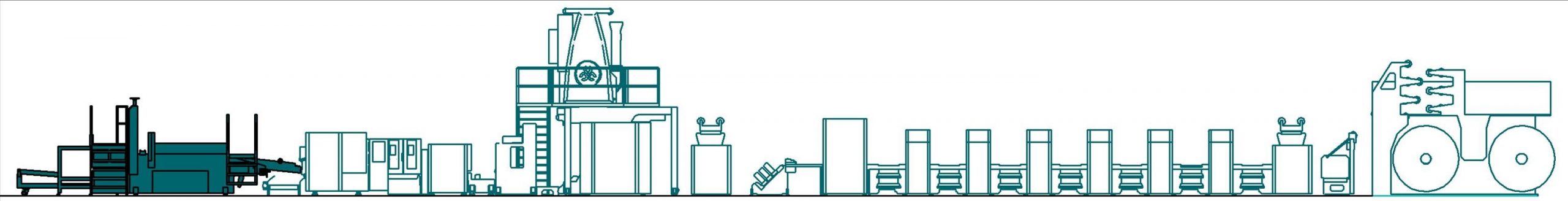

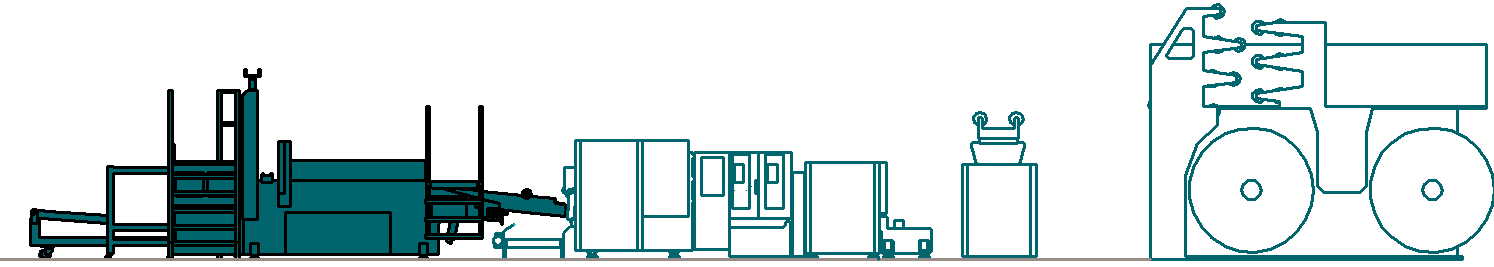

DELIVERY solutions

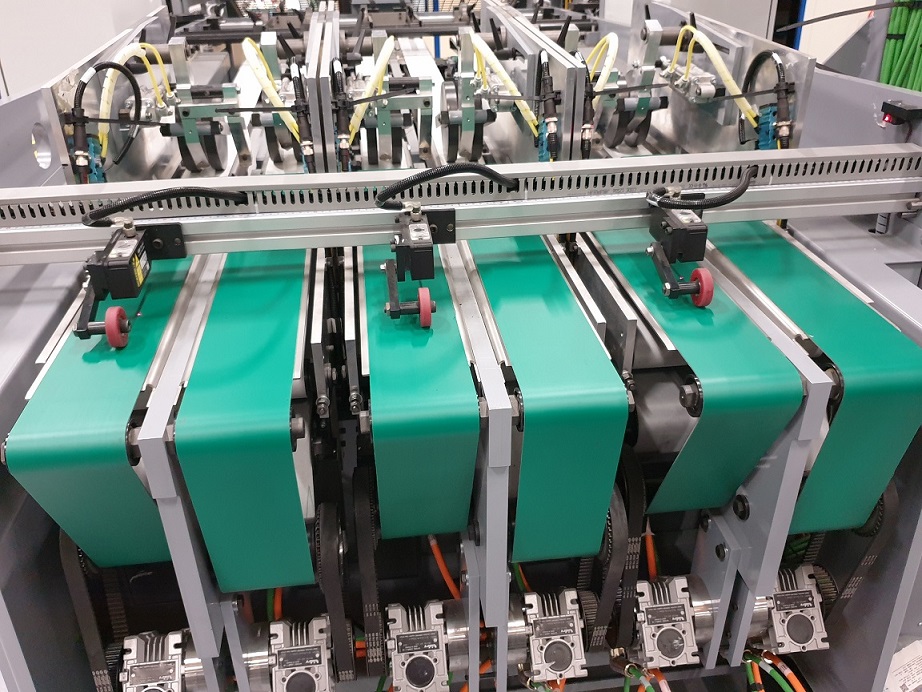

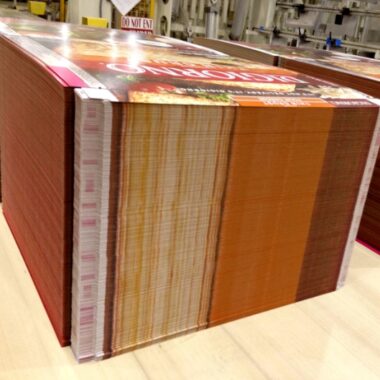

Manage blanks at high speeds, whatever their layout and dimensions or cardboard specifications.

Komori-Chambon designs and manufactures tailor-made solutions from A to Z: transfer, spreader, shingling and stacking.

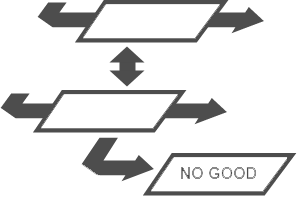

Deliver 100% good blanks with an optional diverter coupled with an optical inspection device.

Optimize your production with automated palletization systems as option.

Komori-Chambon advantages:

- Maximum control and customizable delivery parameters (number of blanks, pile height) up to 450 m/mn

- Independent streams management and optional independent lifts (Multilift system) combined with diverter

- Custom design by application and blank characteristics thanks to longstanding experience

- Flexible configuration (inline installation after Komori-Chambon or OEM die-cutter / offline after platen die-cutter…)