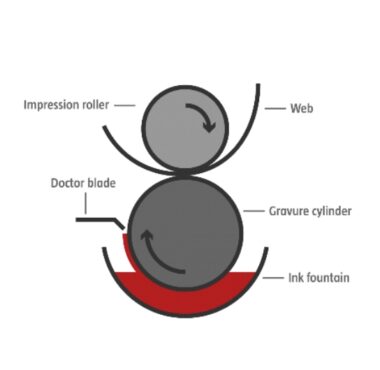

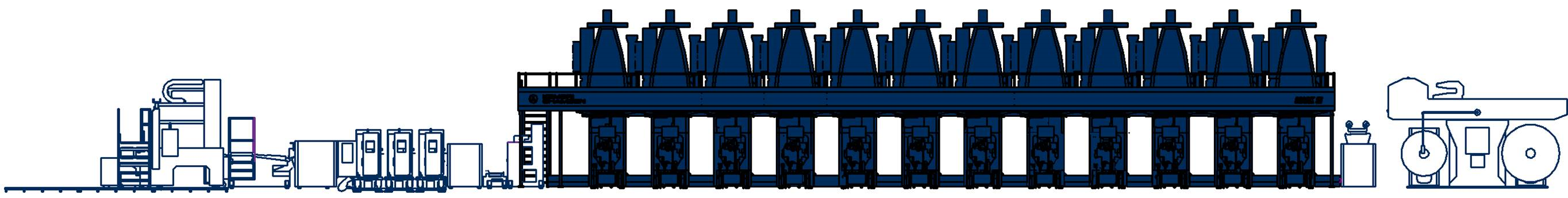

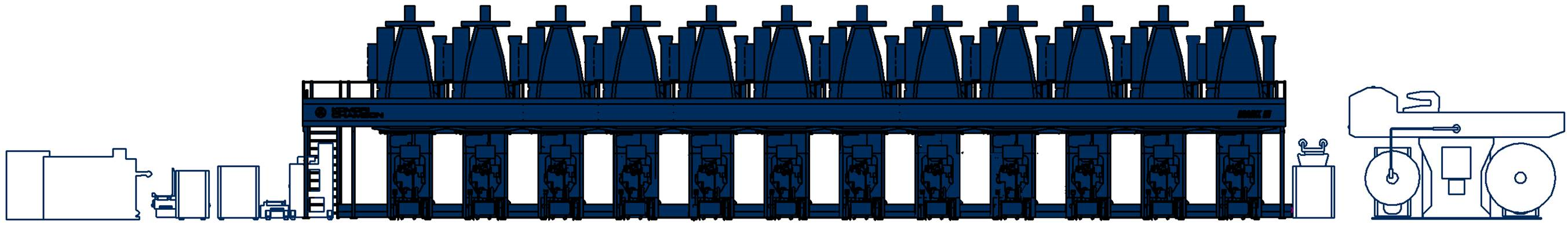

ROTOGRAVURE Solutions

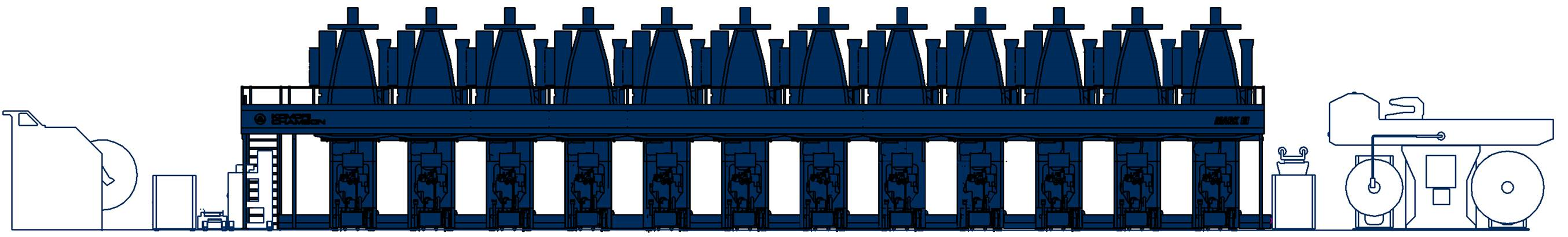

Komori-Chambon rotogravure presses are built upon a long experience exceeding 130 years, enhanced by the latest technologies.

As a true specialist of the packaging printing and converting, we help our customers meets all challenges :

- High color consistency

- Printing quality and stability

- Control of metallic inks

Our presses offer key advantages :

- High speed and low consumption dryers

- Automated and recordable settings

- Full offline preparation of printing trolleys

Combine productivity, safety and ease of use for your serenity