FLEXOGRAPHIC solutions

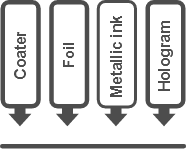

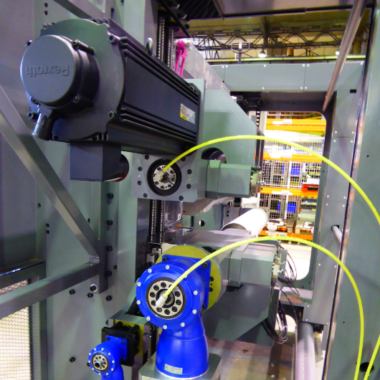

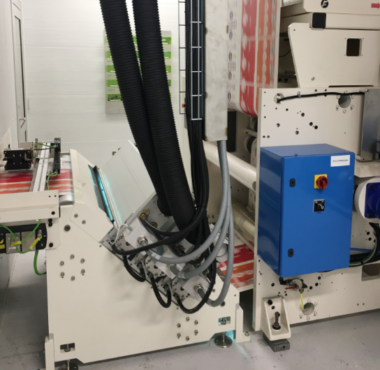

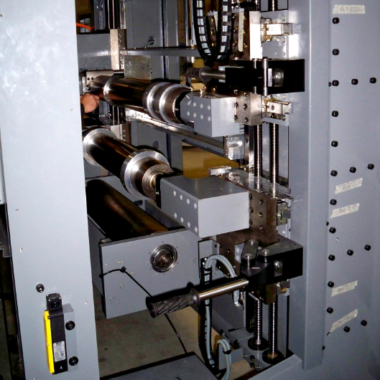

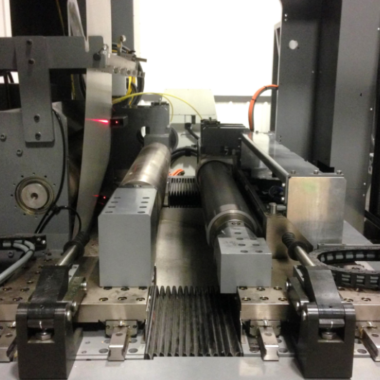

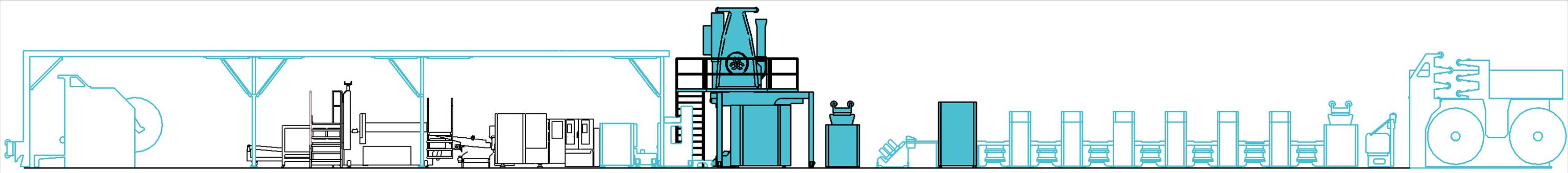

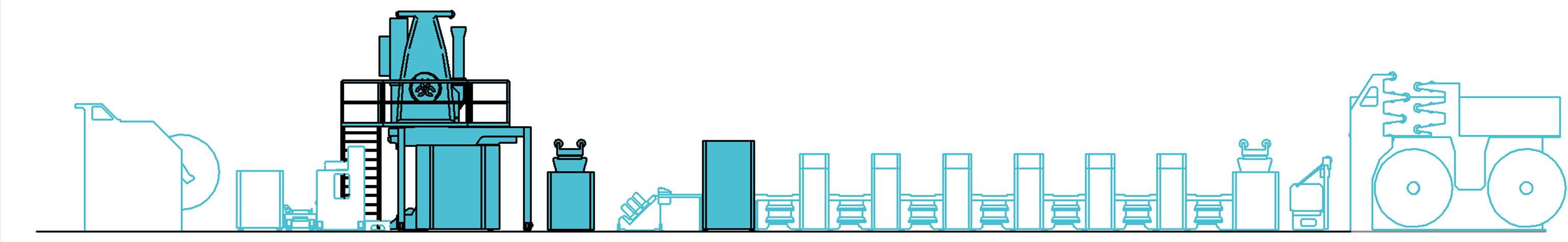

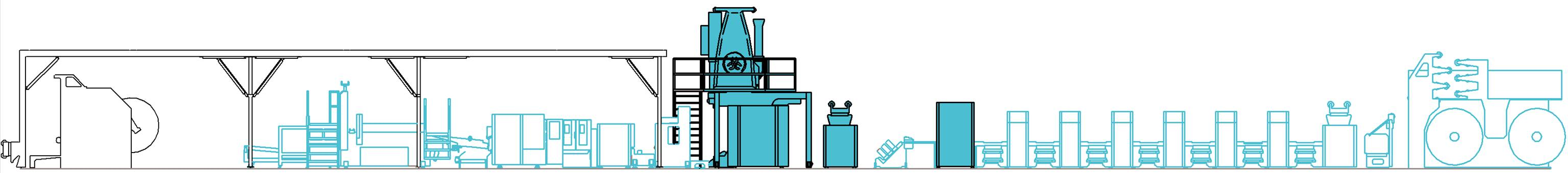

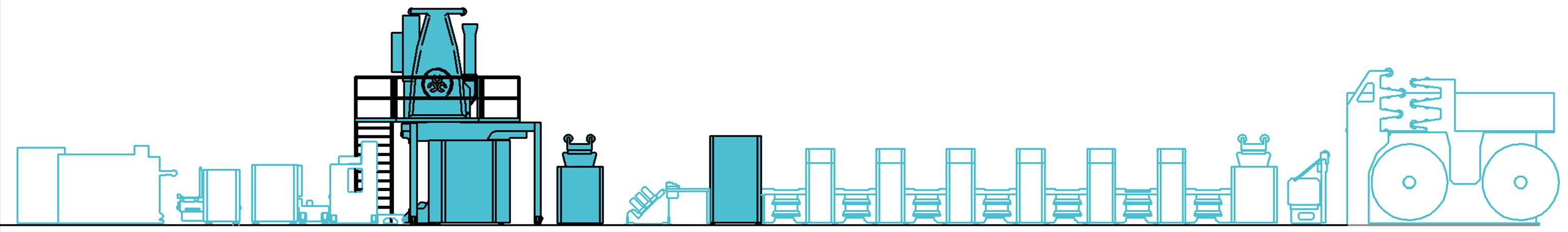

Our flexographic units are designed for printing and coating applications.

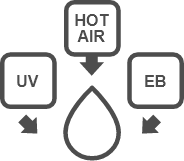

We offer either vertical or horizontal web path configurations, with air or UV dryers.

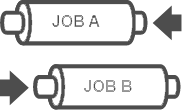

Using flexo units on an offset line or on a rotogravure line as auxiliary units is a relevant choice for coating applications or reverse printing (for instance couponing). This hybrid configuration grants a great versatility, all the more since the make-ready of the flexo units is made very easily thanks to the sleeve-type cylinders.